Basic Info.

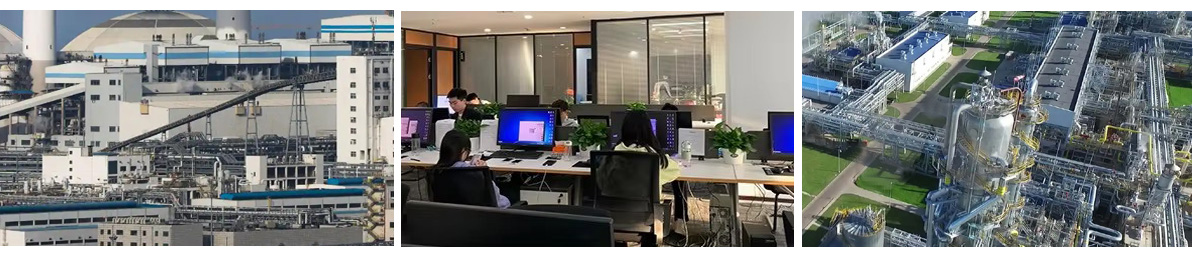

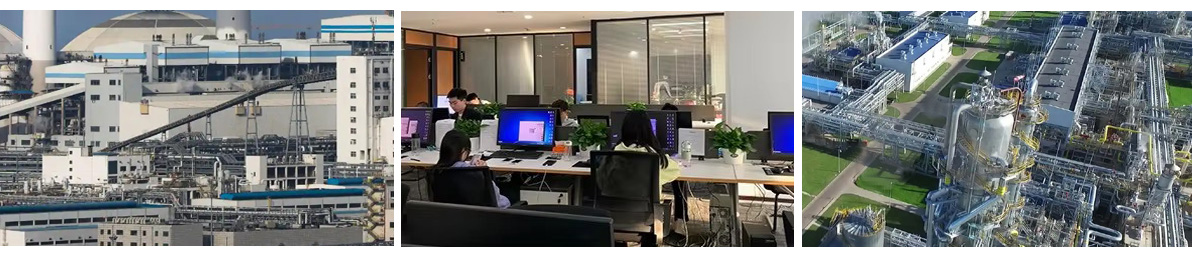

Company profile

Black Silicon Carbide Introduction

Because of the rarity of natural moissanite, most silicon carbide is synthetic. It is used as an abrasive, and more recently as a semiconductor and diamond simulant of gem quality. The simplest manufacturing process is to combine silica sand and carbon in an Acheson graphite electric resistance furnace at a high temperature, between 1,600 ¡ãC (2,910 ¡ãF) and 2,500 ¡ãC (4,530 ¡ãF). Fine SiO2 particles in plant material (e.g. rice husks) can be converted to SiC by heating in the excess carbon from the organic material. The silica fume, which is a byproduct of producing silicon metal and ferrosilicon alloys, also can be converted to SiC by heating with graphite at 1,500 ¡ãC (2,730 ¡ãF).

Add Your Comments

Your email address will not be published. Required fields are marked *